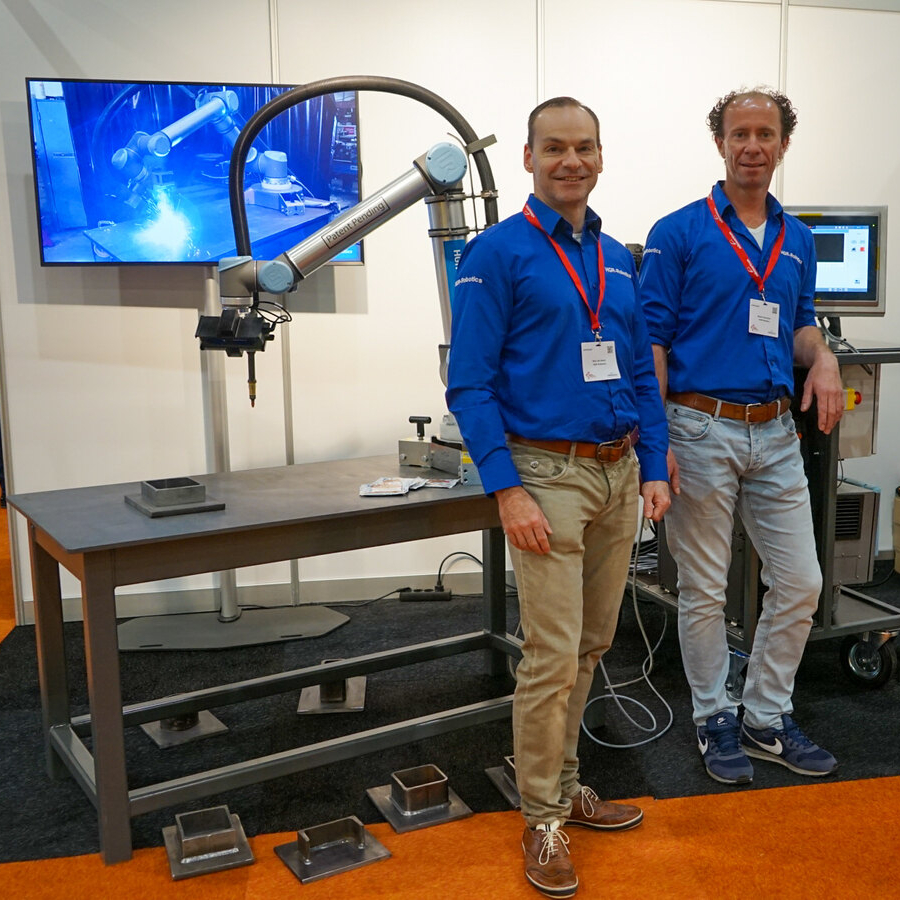

Become a market leader in sustainable innovation

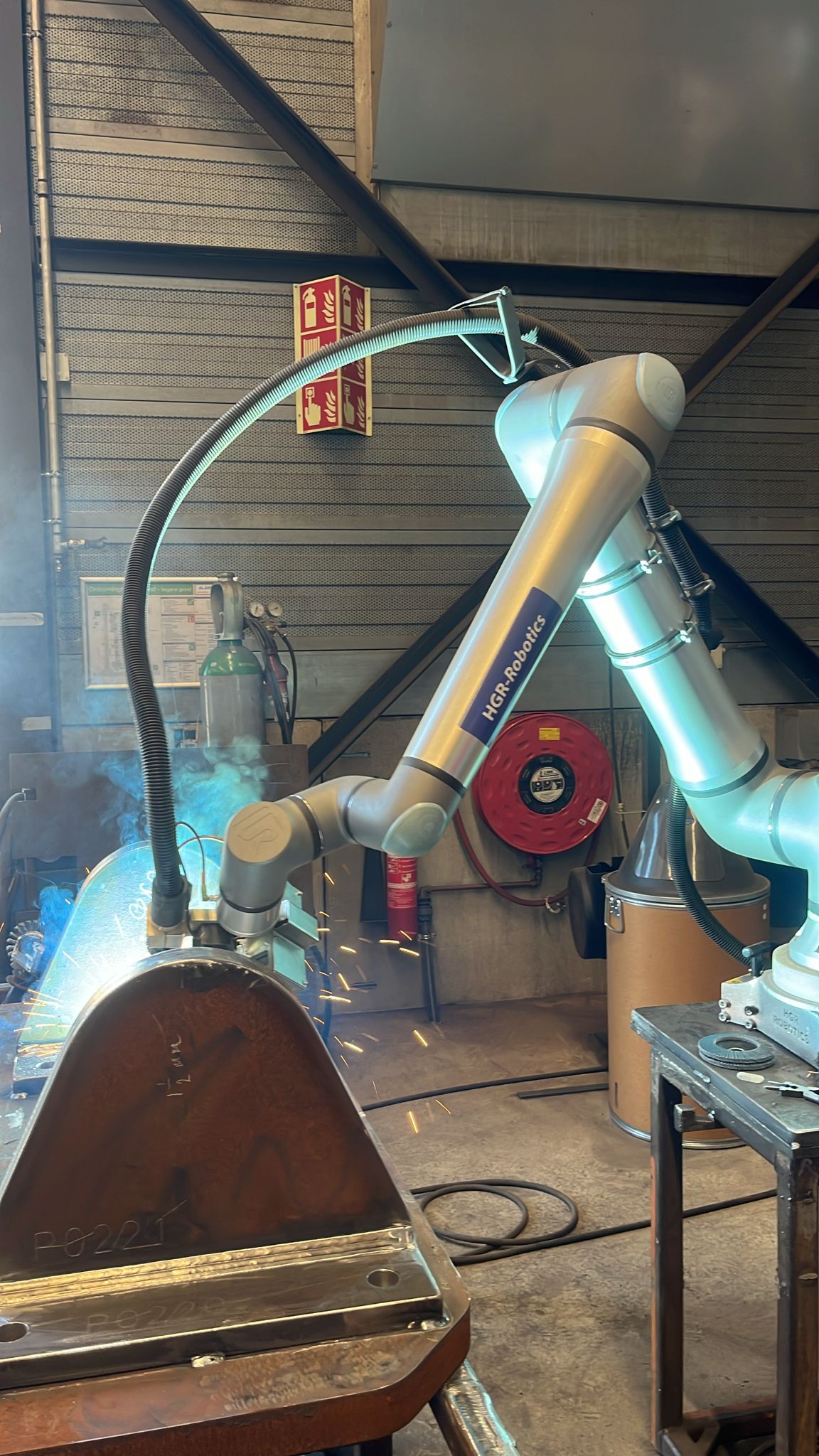

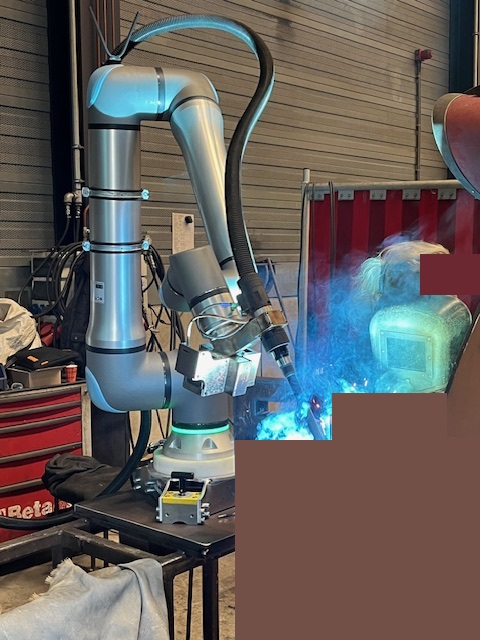

You want to innovate with your company and respond to the latest trends, insights and equipment. The world doesn't stand still, so neither should you. A well-functioning welding robot should not be missing in a modern machine park. Reliable, precise, flexible and according to the highest quality requirements.